Tykkelsesbrettmaskin

Qingdao Kangrui Machinery Co., Ltd.

Our main products are plastic extrusion production lines

The main products are popular in the domestic market, such as the East China market, Southwest market, Northeast market, Central China market, etc. The products are also exported to international markets, including Russia, Australia, Southeast Asia, the Middle East, and Eastern Europe. Africa and other countries have good cooperation with these countries

Final Priduct

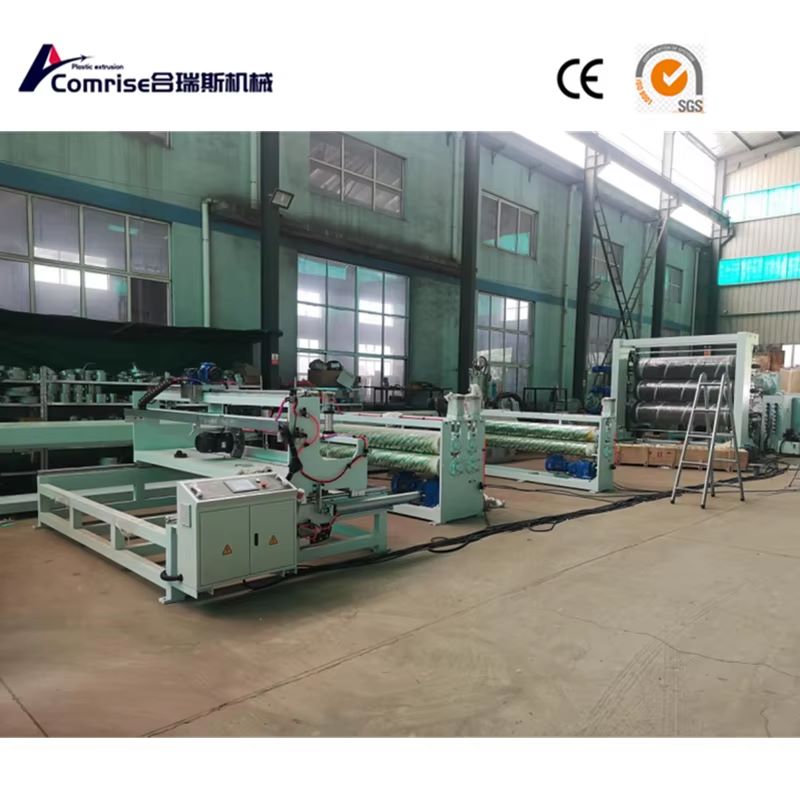

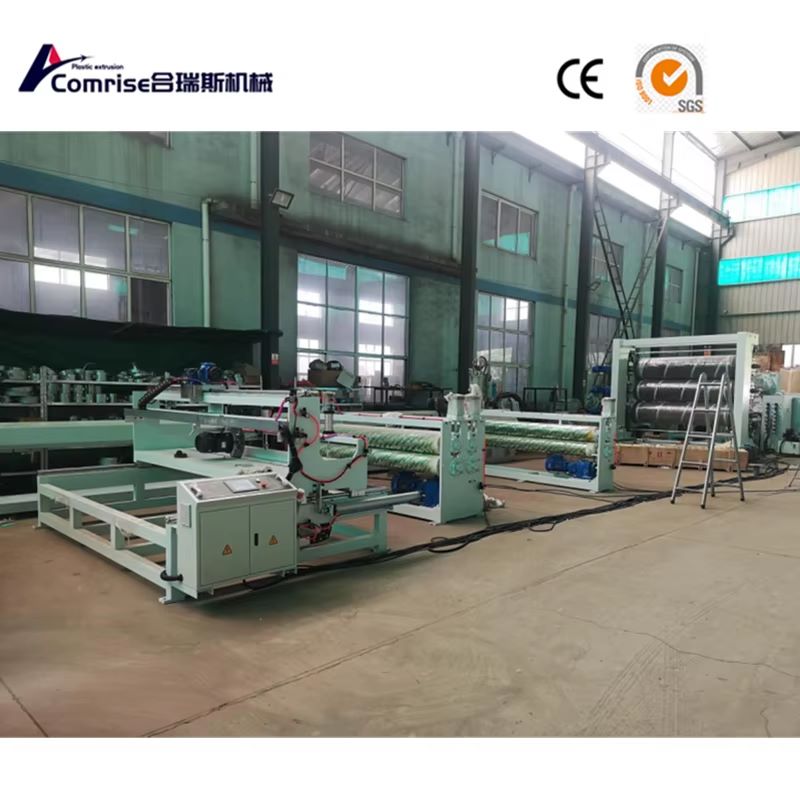

Thickness Board Machine

PP/PE/PVC thick plates have the characteristics of light weight, uniform thickness, smooth surface, good heat resistance, high mechanical strength, excellent chemical stability, good electrical insulation, and non toxicity. Widely used in chemical containers, electronic appliances, machinery, pharmaceuticals, and water treatment, etc

1. High capacity, approximately 400-550kg/h (for SJ130 single screw)

2. Energy saving: 20% more energy-efficient than ordinary machines

3. The operation fully embodies the principles of ergonomics, which can make the functions more complete and the operation simpler.

4. Equipped with mold temperature control, stainless steel pump body, precise temperature control from room temperature to 300 ℃, temperature accuracy within ± 1 ℃, fully temperature controlled, fast heating, good temperature maintenance, long service life, saving time and energ

Technical data

product description

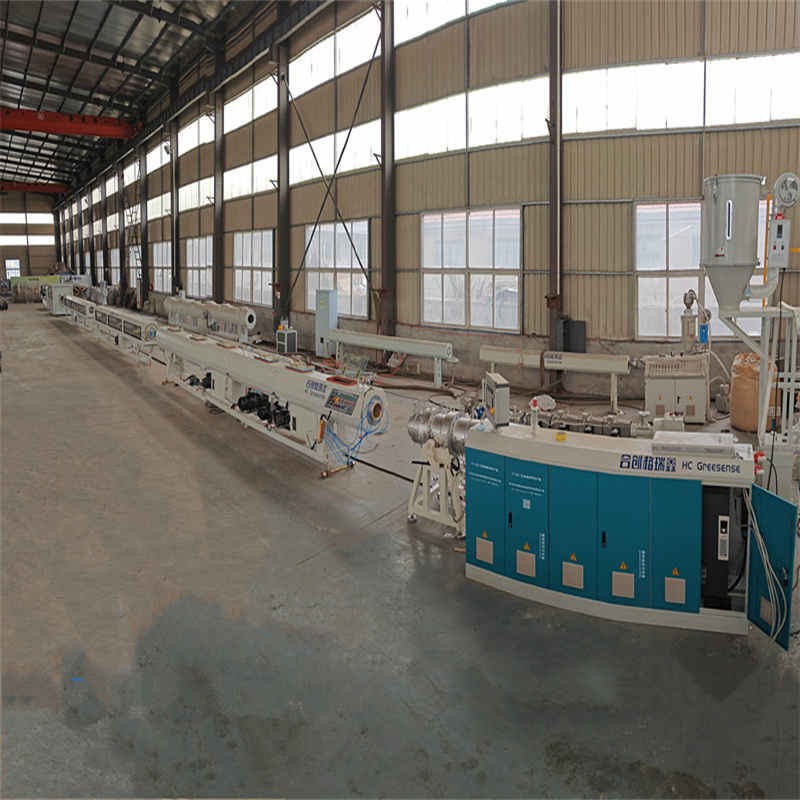

1. The special screw design can effectively improve the plasticization rate, with a production capacity of up to 800 kg/h.

2. Optimized electrical design can achieve precise adjustment and automatic control.

3. The production line adopts Siemens motors, ABB frequency converters, Schneider contactors, Siemens PLC control systems, and Siemens touch screens. Reliable electrical components and specially designed programs can ensure smooth machine operation, save power, and reduce waste.

1.Extruder

World renowned brands of electrical components, such as Siemens, ABB, etc;

High torque gearbox using NSK/SKF bearings;

Siemens/WEG original motors achieve global after-sales service;

• Bimetallic screws and barrels;

Intelligent PLC control system with user-friendly interface.

2.T-shaped die head

Coating hanger type

-5CrNiMo steel material

-Suitable for sheet metal, sheet metal

3.Three roller Calender

• Compacting driving by hydraulic

• Rollers are driven separately and speed control by frequency inverter or servo motor

• Temperature controller is include

• Independent operation panel for easy operation

• Equipped with lamination device

4.Cooling bracket and haul off

•Multi-group cooling rollers;

•Speed control by frequency inverter

• Compacting driving by pneumatic

• With adopts wear-resisting rubber roller

Cooling bracket and haul off

•Multi-group cooling rollers;

•Speed control by frequency inverter

• Compacting driving by pneumatic

• With adopts wear-resisting rubber roller

About Us

Our Advantages

High Production Efficiency:

Advanced extrusion technology ensures high output and consistent quality.

Automated control systems for precise operation and reduced labor costs.

Versatile Material Handling:

Capable of processing a wide range of polyethylene grades, including HDPE, MDPE, and LDPE.

Flexible production settings to accommodate different pipe diameters and wall thicknesses.

User-Friendly Interface:

Intuitive control panel with touch screen display for easy operation and monitoring.

Real-time data tracking and production statistics for better process control.

Robust Construction:

Heavy-duty frame and components for durability and long service life.

Low maintenance requirements and easy access for routine servicing.

Environmental Compliance:

Energy-efficient design to reduce power consumption and operating costs.

Minimal waste generation and recycling options for sustainable production.

GET A QUOTATION NOW

- View as

Tykk brettproduksjonslinje

ComRISE PP-tykkplateproduksjonslinje: PP tykk plate er mye brukt i kjemisk industri, matindustri, antikorrosjonsindustri, rensindustri, produksjonsfabrikk for miljøvernutstyr. Tykke brettproduksjonslinjer er den mest stabile produksjonslinjen som er nyutviklet av Gwell foran sine jevnaldrende. Glassfiberarmert PP -tykk plate kan lages av leverandøren av dobbel maskinserie.

Les merSend forespørselPlast tykt brettproduksjonslinje

Kjennetegn på PP, PE, ABS, PVC tykk tavleproduksjonslinje: Produkter produsert av PP, PE-brettproduksjonslinjefunksjoner med påvirkningsmotstand, korrosjonsmotstand, høy temperaturmotstand, ikke-giftig og smakløs, glatt overflateutseende, lav tetthet, lett vekt, enkel prosessering, god størrelse, rigiditet, god varmebestandighet, ingen giftig gass frigjort under welding.

Les merSend forespørselTykke produksjonslinjer for ekstrudering

Qingdao ComRISE Machinery Hovedproduksjonslinje inkludert avansert HDPE-rør ekstruderingsmaskin, PE med stor diameter hulveggsviklingsrørproduksjonslinje, solid veggviklingsrørmaskin med høykvalitets PPR kulde og varmtvannsforsyningsrørproduksjonslinje, den indre rib-vindpiksen og den kontinuerlige pikspissen. Hul veggproduksjonslinje, den plastbelagte korrugerte rørproduksjonslinjen, PE Black Jacket Isulation Pipe Production Line og PE Sheet/Board Production Line. HC har mer enn 20 typer nye produkter, som selges verden som Russland, Sørøst -Asia, Midt -Østen og Afrika.

Les merSend forespørsel